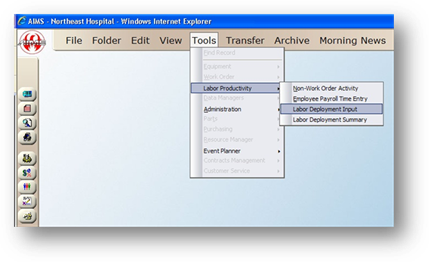

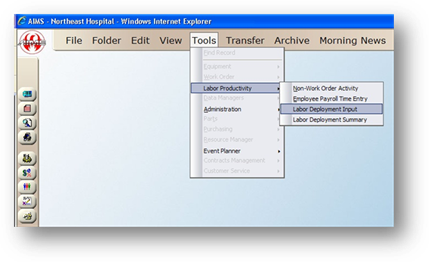

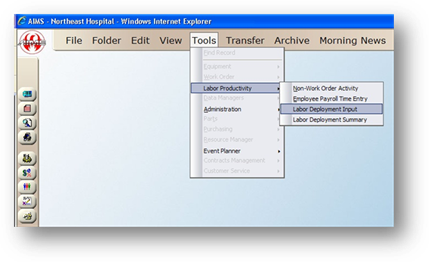

1. Open the Labor Deployment Input Screen by selecting Tools > Labor Productivity > Labor Deployment Input.

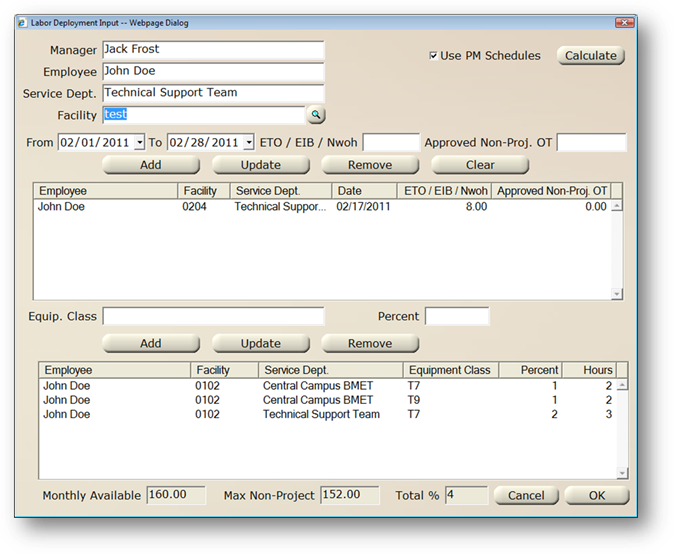

2. Select a Manager from the valid entry list.

3. Select an Employee from the valid entry list.

4. Select a Service Department from the valid entry list.

5. Select a Facility from the valid entry list.

6. Enter the date range you want to enter the data for.

7. Enter the number of hours for ETO(Estimated Time Off)/EIB(Extended Illness Bank)/Nwoh(Non Work Order Hours) for the date range.

8. Enter the number of hours for Approved Non-Project OT for the date range.

9. Click Add.

Analyze an employee’s projected work hours using known values for planned maintenance and an average value for corrective maintenance, based on historical data from the previous year. This information is aggregated by equipment class.

Open the Labor Deployment Input Screen by selecting Tools > Labor Productivity > Labor Deployment Input.

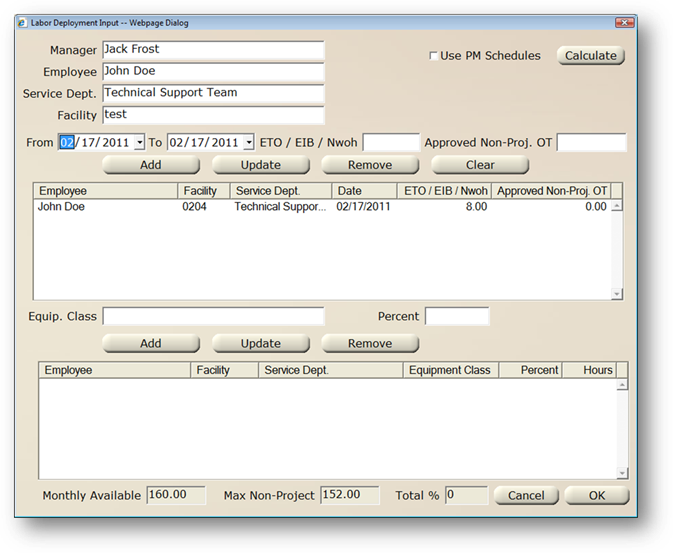

1. Select a Manager from the valid entry list.

2. Select an Employee from the valid entry list.

3. Select a Service Department from the valid entry list.

4. Select a Facility from the valid entry list.

5. Enter the date range for PMs to use in the calculation.

6. Check “Use PM Schedules” (to calculate using open PM’s and upcoming PM’s for the time period specified).

7. Click the Calculate button.